Dan Barlow's Webpage

Computer Numeric Control

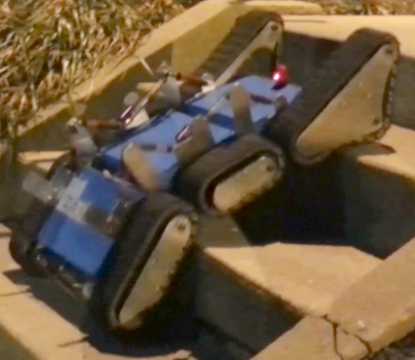

I assisted Transcend Robotics with their ground drone development program by milling the aluminum parts for five robots. I received the part specifications as SVG outlines, converted them to Gcode tool paths, and operated the mill. I developed an improvement of the fore tread mechanism to allow tensioning of the tread.

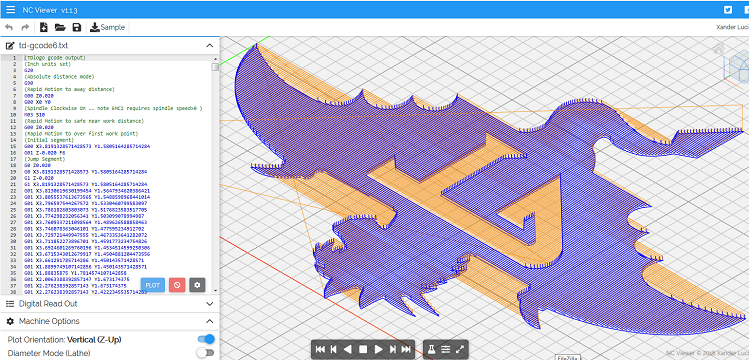

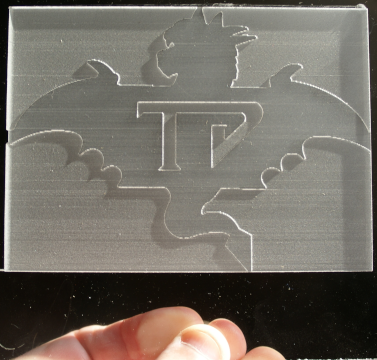

I also write scripts to create custom toolpaths for artistic effect. Here's an example of logos milled into acrylic with a 1/16 ball end mill to create a dimensional frosted illumination.

The supplied graphic is SVG with both straight and bezier segments. The shaded interior should be recessed.

I first wrote a script to graph the SVG file so I could verify the paths. I looked up the Bezier function on wikipedia and implemented the math.

I chose the machine units as integer coordinates and wrote a geometric intersection routine to clip the raster.

I then wrote the Gcode export functions with setup code templated and raster stepover as a variable.

I tested two variations. The original idea is to have the item milled from the back in reverse, so the profile shadows its background when illuminated by office light.

The customer wanted more contrast when edge lit, so the final work only has the fill raster. It's still reverse milled on the back because that directs more light toward the viewer.

Then the script was given another dataset and repeated.